Replacing Germanium with Chalcogenide Glass in MWIR & LWIR Optical Design

Germanium has historically dominated infrared optical design due to its high refractive index and low dispersion. However, its high cost, strong thermal sensitivity, and incompatibility with scalable manufacturing increasingly limit its suitability for modern infrared systems.

This application note demonstrates that chalcogenide glasses are a fully feasible replacement from optical design, thermal performance, and manufacturing perspectives. With modern design techniques and precision glass molding, chalcogenide-based systems can achieve equivalent or superior performance while enabling cost-effective mass production.

1. Material and Optical Design Feasibility

Replacing Ge with chalcogenide glass does not require material equivalence. Instead, feasibility is achieved through optical design freedom and manufacturing enablement.

Table 1: Key material and optical design trade-offs when replacing Ge with chalcogenide glass.

| Aspect | Germanium (Ge) | Chalcogenide Glass | Design Implication |

|---|---|---|---|

| Refractive Index | ~4.0 | 2.2–2.8 | Lower index compensated by element count and aspheres |

| Dispersion | Very low | Moderate–high | Managed via DOEs or multi-glass correction |

| Lens Count | Low | Moderate | Manufacturing scalability offsets complexity |

| Aspheres | High cost | Mold-friendly | Aspheres become economically feasible |

| Thermal dn/dT | High | Low | Passive athermalization achievable |

2. Optical Performance Equivalence

Published MWIR and LWIR design studies demonstrate that chalcogenide-based optical systems can achieve MTF, distortion, and field performance comparable to Ge benchmarks. Performance equivalence is enabled through modest increases in optical complexity.

Table 2: Optical performance feasibility comparison between Ge and chalcogenide designs.

| Design Type | Lens Count | Special Surfaces | MTF vs Ge | Feasibility |

|---|---|---|---|---|

| 2× Ge | 2 | None | Baseline | Reference |

| 2× ChG | 2 | None | Lower | Not sufficient |

| 2× ChG + DOE | 2 | DOE | Equivalent | Feasible |

| 3× ChG (2 glasses) | 3 | Optional asphere | Equivalent | Feasible |

| 4× ChG (1 glass) | 4 | Asphere | Near-equivalent | Feasible |

From Table 2, a 2-element Ge optical system can be replaced with equivalent MTF performance by the same number of chalcogenide lenses with one DOE surface, or with one aspherical chalcogenide lens plus two other IR optical materials such as ZnSe or ZnS. In some designs — especially where Ge is combined with other materials — Ge can be replaced by an equivalent number of chalcogenide elements with the same surface complexity, as the example below shows.

To illustrate, two designs with the same focal length and F/# — with and without Ge — are compared in Table 3, where IRG denotes chalcogenide glass from Schott:

Table 3: Parameters for two designs with 1Ge+3IRG and 4IRG.

| Parameter | 1Ge + 3IRG | 4IRG |

|---|---|---|

| EFL | 50 mm | 50 mm |

| F/# | 1.0 | 1.0 |

| Detector | 1280×1024, 12 µm | 1280×1024, 12 µm |

| Wavelength | 8–12 µm | 8–12 µm |

| Distortion | ≤1% | ≤1% |

| Relative Illumination | ≥96% | ≥93% |

| TTL | 63.76 mm | 63.89 mm |

| Back Focal Length | 18.03 mm | 14.73 mm |

| Aspheric Surfaces | 2 | 2 |

| DOE Surfaces | 1 | 1 |

| First Lens Coating | DLC/HD/AR | HD/AR |

The optical performance of the 4IRG design is equivalent to the 1Ge+3IRG counterpart, with only the relative illumination at the edges being slightly lower. A further limitation is that DLC coating is not currently available for chalcogenide — this is a coating process limitation rather than a design constraint.

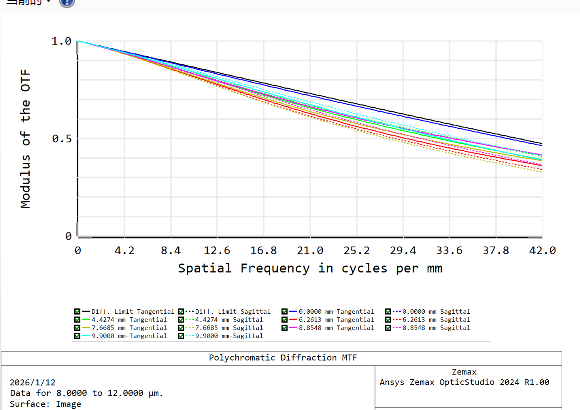

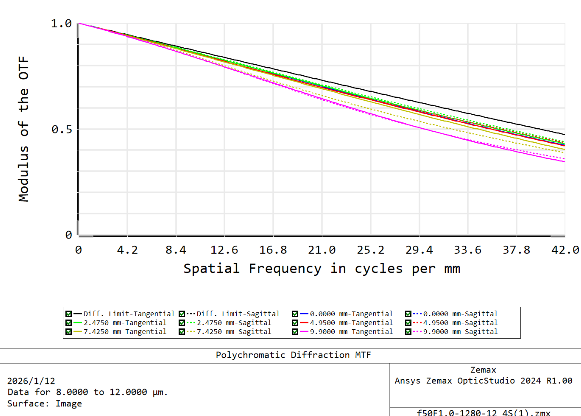

Figure 1: MTF comparison across field — (a) 1Ge+3IRG vs (b) 4IRG.

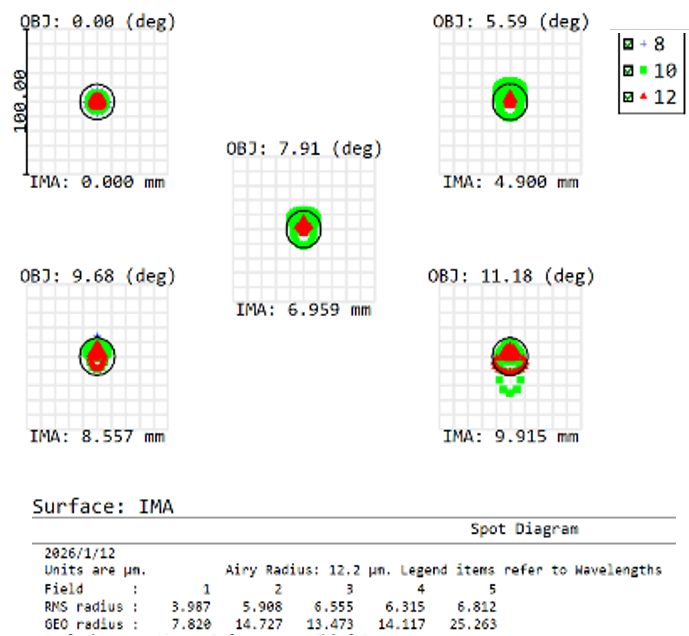

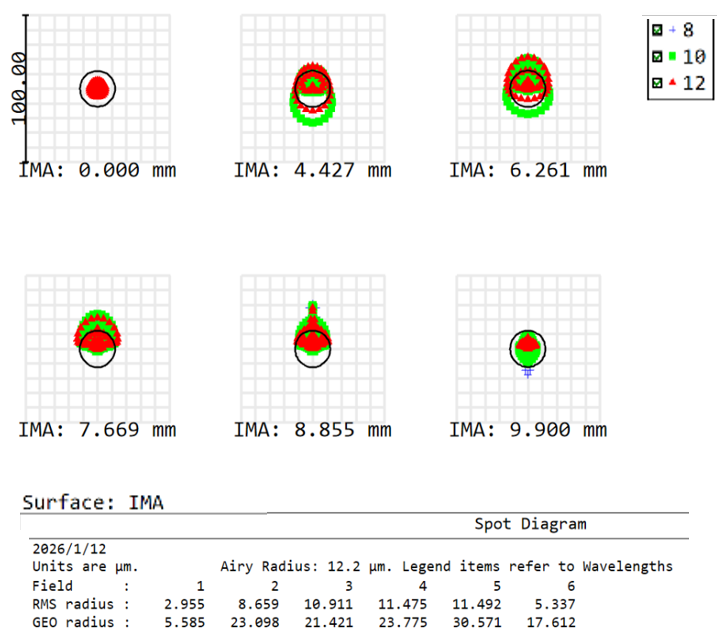

Figure 2: Spot diagram comparison across field — (a) 1Ge+3IRG vs (b) 4IRG.

Figures 1 and 2 show the MTF and spot diagrams for the 1Ge+3IRG and 4IRG configurations. With the same number of lenses, the two systems exhibit similar performance, with the 4IRG design performing slightly better.

3. Thermal Feasibility and System Robustness

Thermal performance is a decisive advantage of chalcogenide glasses. Their low dn/dT enables passive athermal systems, reducing mechanical complexity and improving reliability.

Table 4: Thermal feasibility comparison between Ge and chalcogenide optical systems.

| Metric | Ge System | ChG System | System Impact |

|---|---|---|---|

| dn/dT | High | Low | Reduced focus drift |

| Refocus Needed | Yes | No | Simpler mechanics |

| Thermal Darkening | Possible | None | Higher robustness |

Due to their superior thermal properties, chalcogenide lenses can fulfil athermal requirements, maintaining near-constant performance across a wide temperature range without focal plane adjustment.

4. Manufacturing and Scalability Feasibility

Precision glass molding transforms optical feasibility into economic feasibility. Chalcogenide glasses enable scalable production of complex optical surfaces at low marginal cost.

Table 5: Manufacturing feasibility comparison.

| Manufacturing Aspect | Ge | Chalcogenide Glass | Impact |

|---|---|---|---|

| Fabrication Method | Diamond turning | Precision molding | Cost scaling advantage |

| Asphere Cost | High | Low incremental | Design freedom |

| Volume Scaling | Poor | Excellent | Mass-market ready |

5. Our Existing Germanium-Free Infrared Lenses

We have developed a range of Germanium-free infrared lenses in which Germanium has been replaced by chalcogenide glasses.

Fixed-Focus Lenses

Table 6: Germanium-free fixed-focus infrared lenses.

| Part Number | Focal Length | Wavelength | Detector |

|---|---|---|---|

| IRG6.81.0-17A | 6.8 mm | 8–12 µm | 640×480, 17 µm |

| IRG9.61.0-17A | 9.6 mm | 8–12 µm | 640×480, 17 µm |

| IRG111.0-17A | 11 mm | 8–12 µm | 640×480, 17 µm |

| IRG1001.0-12A | 100 mm | 8–12 µm | 1024×768, 12 µm |

| INFRA-MW133.6-10 | 13 mm | 3.6–4.2 µm | 640×512, 10 µm |

| INFRA-MW253.6-10 | 25 mm | 3.6–4.2 µm | 640×512, 10 µm |

| INFRA-MW503.6-10 | 50 mm | 3.6–4.2 µm | 640×512, 10 µm |

| INFRA-MW13.72.0-15V2 | 13.7 mm | 3–5 µm | 640×512, 15 µm |

| INFRA-MW62.0-15V2 | 6 mm | 3.7–4.8 µm | 640×512, 15 µm |

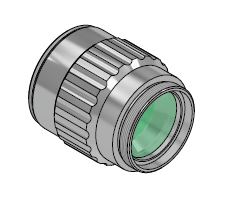

Figure 3: A Germanium-free infrared fixed-focus lens.

Zoom Lenses

Table 7: Germanium-free zoom infrared lens.

| Property | Specification |

|---|---|

| Focal Length | 18–180 mm |

| F/# | 0.8 / 1.2 |

| Wavelength | 8–12 µm |

| Detector | 640×512, 15 µm |

| Focus Range | 3 m – ∞ |

| Focus Type | Auto Focus |

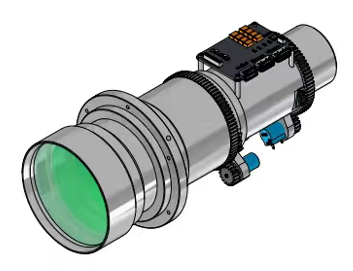

Figure 4: A Germanium-free infrared zoom lens.

Athermal LWIR Lenses

We have developed more than 100 types of athermal LWIR lenses with chalcogenide glass and other non-Ge materials, with focal lengths ranging from 0.9 mm to 110 mm.

Table 8: Athermal LWIR fixed-focus lenses without Germanium.

| Focal Length | F/# | Wavelength | BWD | Sensor |

|---|---|---|---|---|

| 0.9 mm | 1.1 | 8–12 µm | 2.4 mm | 120×90, 12 µm |

| 1.6 mm | 1.0 | 8–14 µm | 2.36 mm | 120×90, 12 µm |

| 3.2 mm | 1.0 | 8–12 µm | 2.53 mm | 256×192, 12 µm |

| 5 mm | 1.0 | 8–12 µm | 6.1 mm | 384×288, 12 µm |

| 10 mm | 1.0 | 8–12 µm | 8.1 mm | 384×288, 17 µm |

| 16.8 mm | 1.0 | 8–12 µm | 8 mm | 640×512, 12 µm |

| 25 mm | 1.0 | 8–12 µm | 10 mm | 640×512, 12 µm |

| 35 mm | 1.0 | 8–12 µm | 10 mm | 1280×1024, 12 µm |

| 50 mm | 1.0 | 8–12 µm | 11 mm | 1280×1024, 12 µm |

| 55 mm | 1.0 | 8–12 µm | 10 mm | 640×512, 12 µm |

| 75 mm | 1.0 | 8–12 µm | 8.075 mm | 1280×1024, 12 µm |

| 110 mm | 1.3 | 8–12 µm | 10.29 mm | 640×512, 17 µm |

6. Why Choose Wavelength Opto-Electronic

Wavelength Opto-Electronic (WOE) combines extensive IR optics expertise with end-to-end manufacturing capabilities, making it an ideal partner for Germanium-free solutions. The company’s integrated operations cover the entire value chain — from in-house chalcogenide glass development and purification to optical design, precision fabrication, coating, and assembly — enabling full production of IR lenses and systems without relying on Ge.

Wavelength’s specialized R&D in chalcogenide materials (including proprietary purification and growth processes) and significant production capacity (~10 tons of chalcogenide glass per year) ensure it can deliver high-performance MWIR/LWIR optics at scale. With decades of IR lens design experience — spanning athermal imaging to continuous zoom systems — and advanced technologies like durable DLC coatings tailored for chalcogenide optics, Wavelength is well positioned to support system designers and manufacturers in deploying scalable, high-performance Ge-free IR optical systems.

7. Conclusion

Replacing Germanium with chalcogenide glasses is not only feasible but strategically advantageous for modern MWIR and LWIR optical systems. Enabled by optical design freedom and precision molding, chalcogenide glasses deliver performance parity, thermal robustness, and scalable manufacturability.